The Role of a PLC Maintenance Technician in Ensuring Smooth Operations

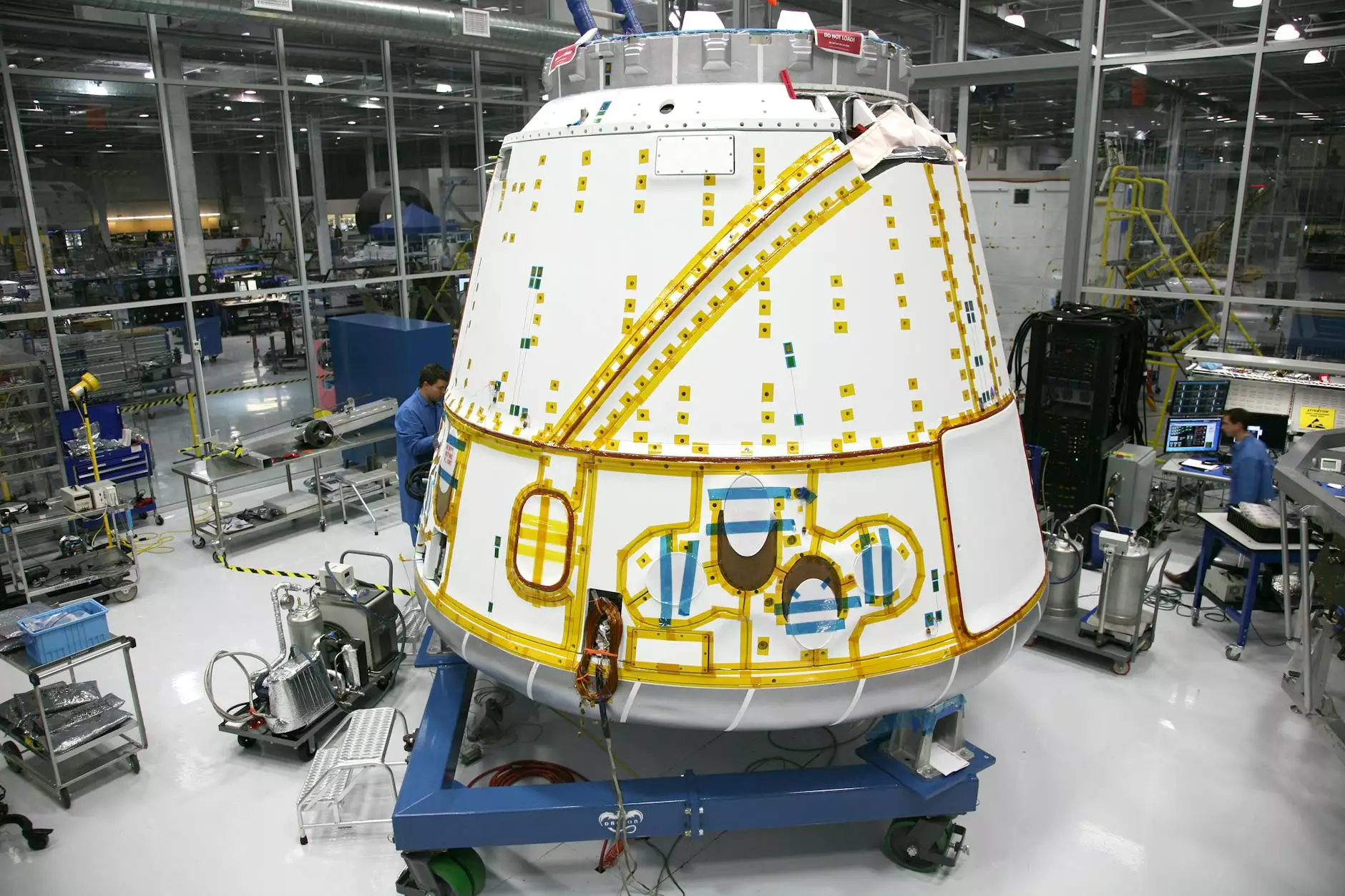

The ever-evolving industrial landscape demands expertise in automation and control systems. One critical component of this domain is the Programmable Logic Controller (PLC), which serves as the brain behind automated processes. To ensure the smooth functioning of PLC systems, businesses rely on skilled PLC maintenance technicians.

Understanding the Function of a PLC Maintenance Technician

A PLC maintenance technician specializes in the installation, maintenance, and repair of PLC systems. They possess in-depth knowledge of electronic components and their integration within complex industrial setups. These technicians play a crucial role in ensuring that PLC systems operate efficiently and reduce downtime, enhancing overall productivity.

The Importance of PLC Maintenance

PLC maintenance is vital for businesses that heavily rely on automation systems. It helps prevent unexpected breakdowns, loss of production, and expensive repairs. By regularly monitoring and maintaining PLC systems, businesses can avoid costly downtimes that can impact their bottom line.

1. Identifying Potential Problems

A skilled PLC maintenance technician can identify potential problems in the early stages. Through routine inspections and diagnostic tests, they can detect any anomalies and address them before they develop into major issues.

2. Enhancing System Performance

Regular maintenance ensures that the PLC system operates at its optimal performance. Technicians perform tasks such as cleaning, lubricating, and calibrating components, ensuring accurate readings and reliable operation.

3. Minimizing Downtime

Unplanned downtime can result in significant financial losses for businesses. PLC maintenance technicians employ preventive measures to minimize downtime, including scheduled maintenance, component replacements, and system updates.

4. Troubleshooting and Repair

In the event of a system failure, PLC maintenance technicians possess the skills to diagnose and resolve issues efficiently. Their expertise in troubleshooting and repair helps to restore operations promptly, reducing production loss.

The Role of Electronic Components in PLC Maintenance

As an electronic components distributor in Canada, QF Automation recognizes the significance of utilizing high-quality components. When it comes to PLC maintenance, the quality and reliability of electronic components are paramount.

QF Automation partners with renowned manufacturers to source top-grade electronic components. This ensures that their clients receive components with exceptional performance and reliability, minimizing the risk of potential failures within the PLC systems.

PLC Repair Services by QF Automation

Alongside their electronic components distribution services, QF Automation excels in PLC repair services. Their team of experienced PLC maintenance technicians possesses a deep understanding of various PLC systems, allowing them to assist businesses in the repair and restoration of malfunctioning systems efficiently.

QF Automation's PLC repair services encompass troubleshooting, component replacement, system reprogramming, and comprehensive testing to ensure that the repaired system operates flawlessly.

Conclusion

PLC maintenance technicians play a vital role in the automation industry. Their expertise in the installation, maintenance, and repair of PLC systems ensures smooth operations, minimal downtime, and optimized performance. Partnering with a reliable electronic components distributor and PLC repair service provider like QF Automation is key to ensuring the longevity and efficiency of automation systems.