Understanding the Importance of Engine Crankshafts in Diesel Engines

The engine crankshaft is often described as the heart of the diesel engine. Its design and functionality are crucial for the engine's performance and efficacy. In this detailed exploration, we will delve into the nuanced workings of the engine crankshaft, its components, and why it is indispensable to diesel engine systems. Additionally, we will discuss how businesses like client-diesel.com serve as efficient suppliers of diesel engine parts, ensuring you have what you need to keep your machinery running smoothly.

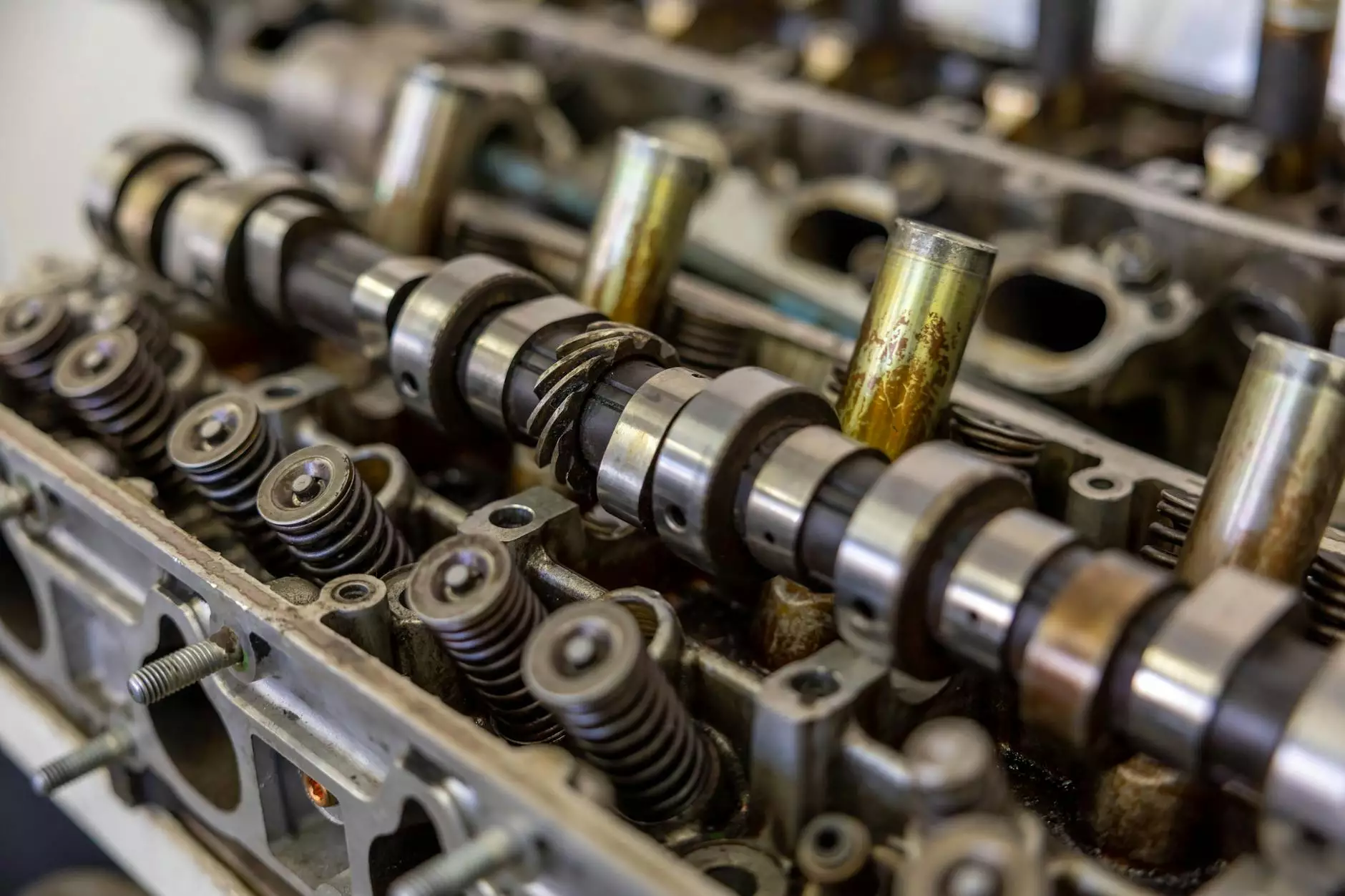

What is an Engine Crankshaft?

The engine crankshaft is a vital component in internal combustion engines, converting the linear motion of the pistons into rotational motion that ultimately powers the vehicle. Typically made from high-strength steel or cast iron, the crankshaft operates under immense pressure and is designed to withstand high temperatures and stress.

Key Functions of the Engine Crankshaft

The engine crankshaft serves several critical functions within a diesel engine:

- Converts Piston Movement: The primary role of the crankshaft is to transform the up-and-down motion of the pistons into a rotational motion that can drive the vehicle's wheels.

- Maintains Engine Balance: A well-designed crankshaft contributes to the overall balance of the engine, reducing vibration and enhancing operational efficiency.

- Supports Other Components: It acts as a central shaft that supports various components like the flywheel and the oil pump, ensuring synchronized operation.

- Facilitates Power Transfer: The crankshaft is essential for the transfer of power to the transmission, which then propels the vehicle.

The Anatomy of an Engine Crankshaft

The structure of an engine crankshaft is complex and comprises several key parts:

- Main Journals: These cylindrical sections connect the crankshaft to the engine block and are where the bearings sit, allowing for smooth rotation.

- Crank Pins: These are offset from the main journals and are attached to the connecting rods, converting the linear motion of pistons to rotational motion.

- Counterweights: Under immense stress, counterweights are added to balance the crankshaft's weight and mitigate vibrations during operation.

- Flange/Keyways: The flange connects the crankshaft to the flywheel, whereas keyways ensure precise alignment between the components.

The Manufacturing Process of Engine Crankshafts

The manufacturing of engine crankshafts involves several intricate stages, ensuring that each piece meets high standards of quality:

- Material Selection: High-grade steel or cast iron is chosen for its durability and ability to withstand high levels of stress.

- Forging: The raw material is forged into shape, which enhances its molecular structure, making it stronger.

- Machining: Precision machining shapes the crankshaft to exact specifications, ensuring that all journal dimensions align perfectly.

- Balancing: The crankshaft must be balanced to avoid vibrations that could lead to engine wear over time.

- Surface Treatment: Applying surface treatments can enhance the crankshaft's resistance to wear and fatigue.

Signs of a Failing Engine Crankshaft

Recognizing the signs of a failing engine crankshaft is crucial for maintenance:

- Unusual Vibrations: Excessive vibrations can indicate imbalance or misalignment, signaling a potential crankshaft issue.

- Engine Noise: Unusual knocking or tapping sounds may suggest that the bearings are worn or the crankshaft is damaged.

- Oil Leaks: If you notice oil leaking from the front of the engine, it might be due to a failing or improperly sealed crankshaft.

- Loss of Power: A decrease in engine performance could indicate internal problems related to the crankshaft.

The Importance of Quality in Engine Crankshaft Replacement

When the time comes to replace a failing engine crankshaft, quality should never be compromised. High-quality replacement parts can ensure:

- Enhanced Performance: A well-manufactured crankshaft improves the overall performance of the engine.

- Longevity: Quality parts typically last longer, providing better value over time.

- Increased Reliability: When you opt for reputable suppliers like client-diesel.com, you can trust that the parts you receive will be reliable and perform optimally.

- Warranty and Support: Many reputable suppliers offer warranty options and customer support, ensuring you have assistance if issues arise.

Finding Reliable Spare Parts Suppliers

As the engine crankshaft is a critical component in diesel engines, finding a trusted supplier for diesel engine parts is essential. Here are some strategies to help you identify reliable suppliers:

- Research and Reviews: Look for customer reviews and testimonials related to spare parts suppliers. Feedback from other users can provide insights into quality and service levels.

- Industry Experience: Choose suppliers with a long-standing presence in the diesel engine parts market. Experience often correlates with reliability and product quality.

- Certifications: Look for suppliers that hold relevant industry certifications, which can be indicative of their commitment to quality standards.

- Range of Products: A good supplier should offer a wide variety of parts, including the engine crankshaft, along with related components.

- Customer Service: Exceptional customer service is vital. Choose suppliers who are responsive and willing to answer questions regarding their products.

The Future of Engine Crankshafts in Diesel Technology

The future of diesel engines, including the engine crankshaft, is evolving. Advances in technology and engineering practices mean that we can expect improvements in:

- Material Science: Continuing enhancements in material properties will lead to lighter, stronger, and more resilient crankshafts.

- Efficiency: With more attention being paid to efficiency, future crankshafts will be designed to minimize energy loss, contributing to better fuel economy.

- Hybrid Technologies: As hybrid technologies emerge, the design and function of crankshafts may adapt to fit new engine configurations.

Conclusion

The engine crankshaft is not only a pivotal component of diesel engines but a remarkable piece of engineering that exemplifies the complexity and precision required in automotive technology. Understanding its functionality, the manufacturing process, and signs of wear can help users maintain their engines effectively. For those in need of parts, sourcing from reputable suppliers such as client-diesel.com guarantees access to high-quality, reliable engine parts that will ultimately contribute to the longevity and effectiveness of diesel engines.